DTF (Direct-To-Film) is a modern textile printing method that combines simplicity with high quality. The process relies on three key components – DTF films, specialized inks and adhesive powders, which together ensure a durable and detailed print.

Advantages of DTF Technology:

Special DTF films are used as the base for printing the design, which is then transferred onto the fabric. Their coated surface holds the ink perfectly, resulting in sharp and vibrant colors. Available as Instant hot peel (removal while still warm), they allow you to adapt production to your workflow.

30 cm/100lm DTF film 75 mic. Thick., Matt/Matt, Instant Hot Peel

60 cm/100lm DTF film 75 mic. Thick., Matt/Matt, Instant Hot Peel

80 cm/100lm DTF film 75 mic. Thick., Matt/Matt, Instant Hot Peel

DTF printing uses pigmented CMYK inks combined with a white layer that ensures excellent coverage even on dark fabrics. High-quality DTF inks deliver vivid shades, elasticity, and wash resistance, while maintaining compatibility with different films and textiles.

CMYK + White + Cleaner

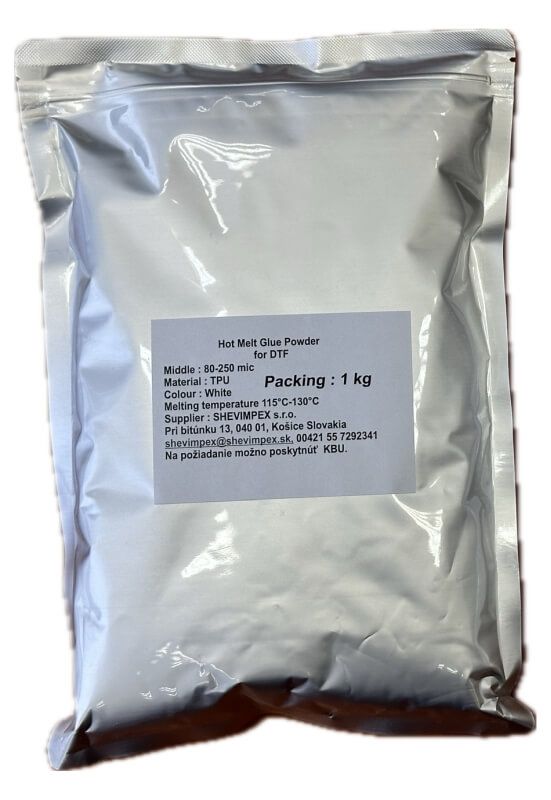

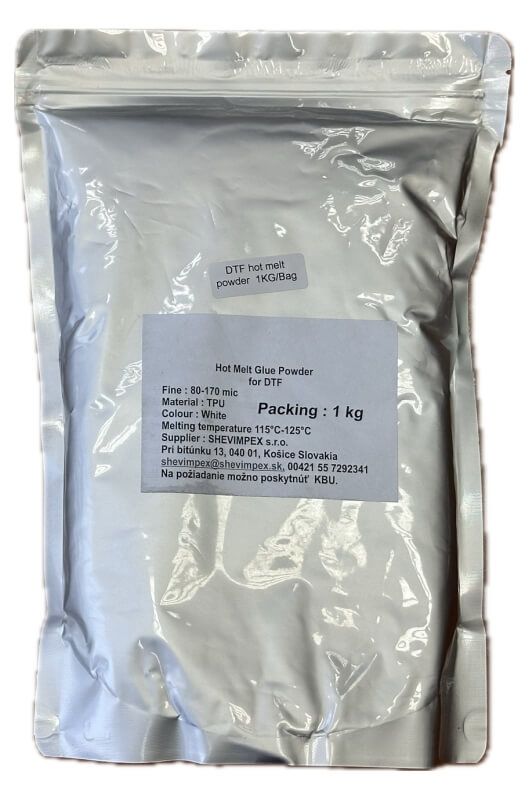

After printing, a polyurethane adhesive powder is applied onto the wet design. Once cured in a heat press or oven, it creates a strong bond between the print and the fabric. Different powder grain sizes allow for the best results on various fabric types.